Artificial intelligence in photovoltaic production

Five scientific institutions in Germany are currently working together on self-learning production plants that use process data for the permanent optimization of manufacturing. The initiative is aimed at making the settlement of photovoltaic factories in Germany and Europe attractive again.

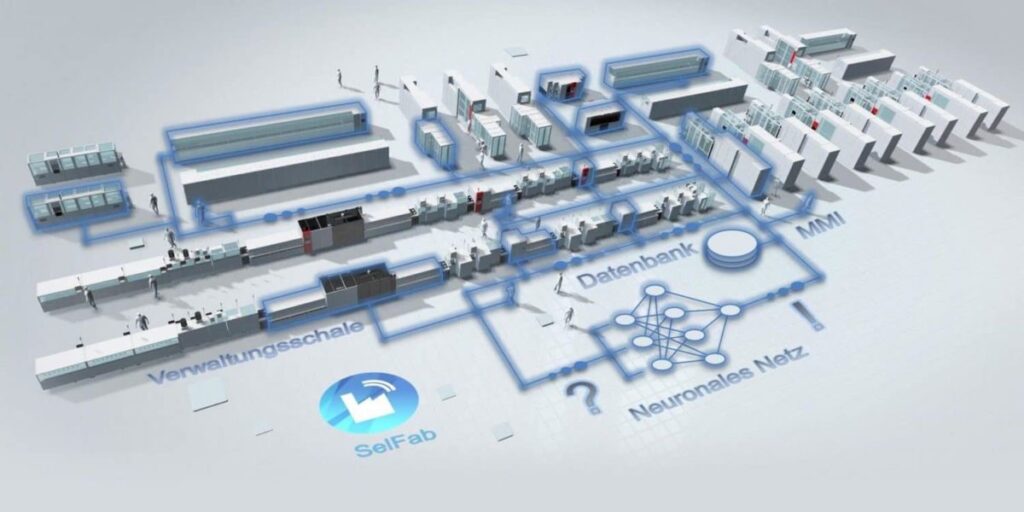

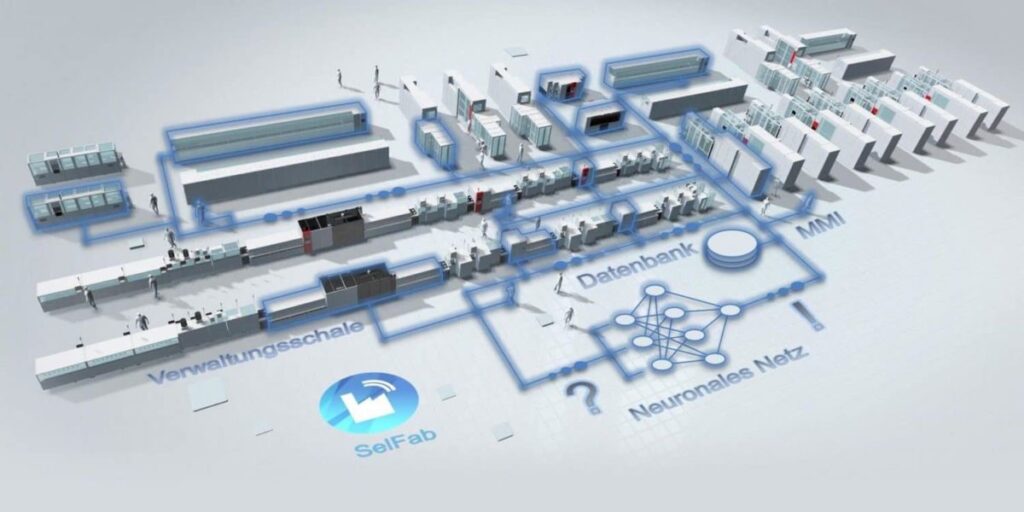

The manufacture of high-tech solar cells and modules requires many complex production processes and materials and the volume of data in production is correspondingly high. According to five scientific institutes from the German state of Baden-Württemberg, this is a great opportunity for the further development and optimization of production. The research centers are working together on the self-learning photovoltaic factory project, or SelFab, which is aimed at developing intelligent PV production systems.

The Fraunhofer Institute for Manufacturing Engineering and Automation IPA, the Fraunhofer Institute for Solar Energy Systems ISE, the International Solar Energy Research Center Konstanz (ISC Konstanz eV), the Institute for Photovoltaics of the University of Stuttgart (ipv) and the Center for Solar energy and hydrogen research Baden-Württemberg (ZSW) are partnering on the SelFab project. The Ministry of Economics and Labor in Baden-Württemberg is funding the project with around €2 million as part of the state’s digitization strategy.

“The cooperation between production automation and photovoltaic research in the field of silicon and CIGS thin-film solar cells creates synergies in the development of the basis for a self-learning solar factory, which increases the scope of the project results and which can be applied to a wide variety of solar technologies,” said Martin Kasperczyk, project coordinator at Fraunhofer IPA.

Analysis of plant and factory data in real-time

The partners created a digital framework for a production line for solar cells and modules by digitizing all relevant production processes in a photovoltaic factory with generic models in order to increase the range of applications and the possible number of companies using it. The digital images provide data and their meaning via common communication interfaces. The partners also developed suitable machine learning methods for this purpose.

According to the researchers, the benefit of this approach is that plant and factory data can be analyzed continuously and in real-time using artificial intelligence. With the help of the comprehensive information, manufacturing processes and products can be optimized.

This was illustrated by the data analyses and their correlation with solar cell efficiency. This is particularly worthwhile in research and development-intensive areas since technological advances can be transferred to production faster and more efficiently.

With the knowledge gained in the project, mechanical and plant engineering for solar cells and modules should be integrated into future intelligent Industry 4.0 factories. According to the project partners, the findings from the project can also be used in other branches of industry beyond the limits of photovoltaics.

The solar industry’s interest in the use of artificial intelligence is great. “With self-learning factories, our engineers have new, innovative tools at their disposal with which we can save time and money in the development of CIGS thin-film modules,” explained Kay Orgassa, CTO of Nice Solar Energy. The company produces thin-film solar modules based on copper, indium, gallium and selenium (CIGS).

From: https://www.pv-magazine.com/2020/12/22/artificial-intelligence-in-photovoltaic-production/