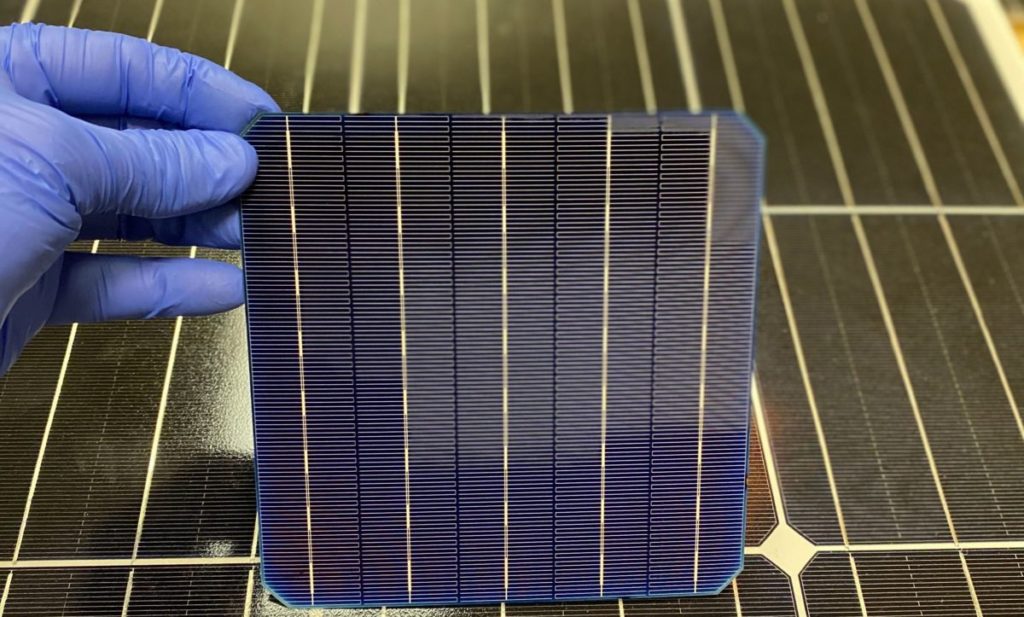

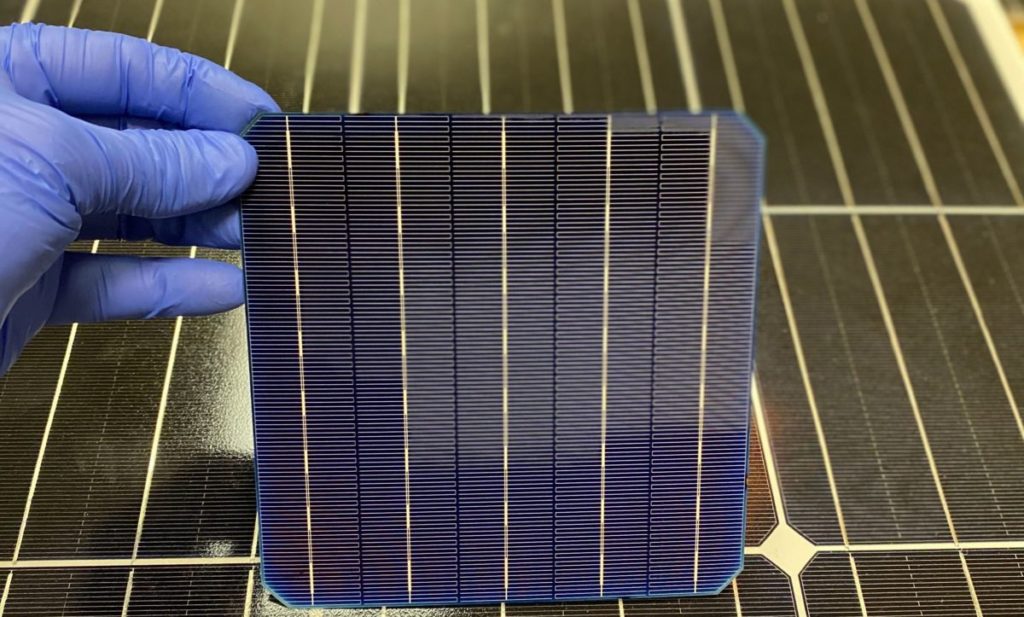

New PV cell architecture creates resistively bounded subcells

Solar Inventions, the winners of the first American-Made Solar Prize, plan to commercialize their newest product, which is claimed to reduce silver content and increase module power, while potentially saving manufacturers up to $1 million per year.

While PV system costs are falling faster than anticipated, there is one module component that isn’t following this trend, and is actually rising in cost significantly: silver. The price of the material has risen by nearly 40% from a year ago, but one company claims it has created a solution that could reduce silver costs by 3%, while also increasing PV module output.

Solar Inventions, the winners of the first American-Made Solar Prize and the creators of Configurable Current Cell (C3) subcell technology – a new PV cell architecture that creates resistively bounded subcells. The idea of creating subcells is nothing new, but Solar Inventions and its chief scientist, Dr. Benjamin Damiani, have been able to develop a way to create these subcells more efficiently, without specialized processing. According to the company’s first white paper, manufacturers are able to utilize C3 with just small changes in metallization print patterns and selective doping. This is achievable via minor print screen modifications and marginal changes to production lines, as C3 configures the subcells in parallel to a cell’s traditional busbars.

The technology works with 95% of all silicon cell architectures, including monocrystalline, polycrystalline, PERC, HJT, and bifacial tech.